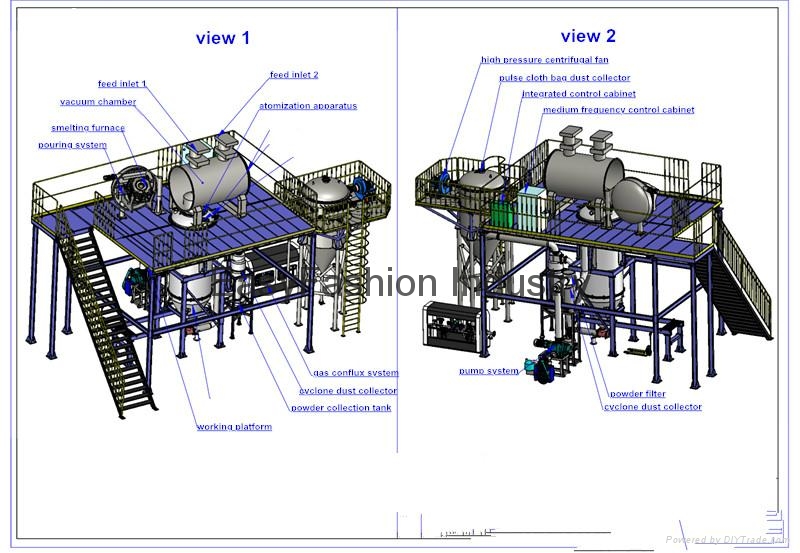

Vacuum gas atomization powder manufacturing equipmentI(gas atomizer)

Model No.︰EF-GAPME

Brand Name︰EasyFahion

Country of Origin︰China

Unit Price︰US $ 200000 / pc

Minimum Order︰1 pc

Product Description

Vacuum gas atomization powder manufacturing method is the newly-developed technique in the metal powder manufacturing industry in recent years. It is characterized by simple technique, easily-mastered technology, not easily oxidized materials, high degree of automation and metal powder fast tempering. The specific technique is the melting, refining and degassing of alloy (metal) in the induction furnace and the melted metal liquid is poured into insulation crucible and then flows into lead-in tube and nozzle. The melting current is atomized by high pressure gas current. The atomized metal powder conducts solidification, subsidence and into the powder collecting tank. The fine powder goes into the cyclone separator with the air current. Finally the gas is discharged outside the furnace and collects the gas and the fine powder goes into the cyclone separator.

II, Main Technical Parameters:

|

Model |

ZGW - 10 |

ZGW - 25 |

ZGW - 50 |

ZGW - 100 |

ZGW - 200 |

|

Capacity ( calculated in steel) |

10kg |

25kg |

50kg |

100kg |

200kg |

|

Pressure rising rate |

0.133Pa/min |

||||

|

Ultimate vacuum degree |

6 × 10-2Pa |

||||

|

Working vacuum degree |

6 × 10-1Pa |

||||

|

Input power source |

380V, three-phase, 50Hz |

||||

|

Output frequency |

4000 Hz |

2500 Hz |

2000Hz |

1000Hz |

1000Hz |

|

Medium power of power source |

60 kW |

100 kW |

160kW |

160kW |

250kW |

|

Output voltage |

375V |

||||

|

Cooling water pressure |

0.2~0.4MPa |

||||

|

Water inflow temperature |

20 °C |

||||

Payment Terms︰ TT

Product Image